Post-consumer plastic waste amounts to 32.8 million tons per year in Europe

Only 13.2 million tons of sorted plastic waste can go into mechanical and chemical recycling

19.6 million tons of mixed plastic waste are incinerated or go to landfills causing tremendous environmental issues

The Solution of the Problem

With its pyrolysis process, Tubis provides true circularity for plastic waste

1

2

3

4

5

6

7

1

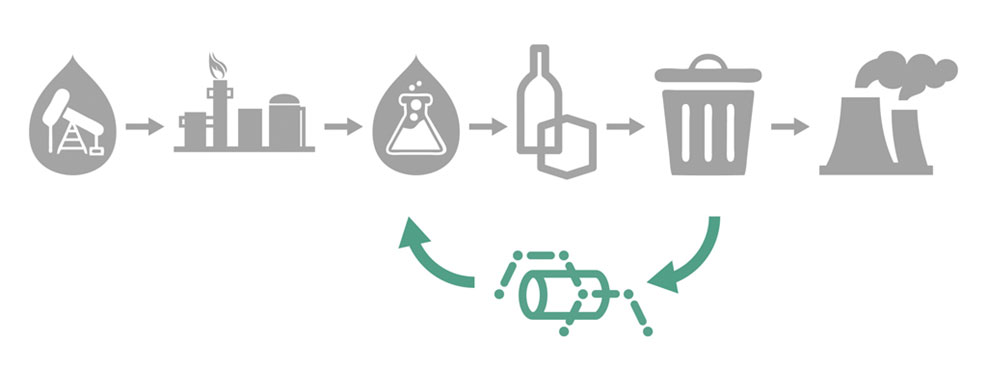

Crude oil is a mixture of naturally occurring hydrocarbons, often containing high amount of sulphur and other impurities.

2

Crude oil is processed and refined into more useful products such as petroleum naphtha, gasoline, diesel fuel, asphalt base, heating oil, kerosene and liquefied petroleum gas.

3

Most plastics are made from one of two feedstock raw materials, crude oil (via the refinery product naphtha) or natural gas.

4

Plastics are used for many industrial as well as consumer products including e.g. packaging (food, appliances, toys, etc.)

5

Plastic waste (industrial as well as household) is predominantly disposed through recycling/waste companies, where it is partly recycled (e.g. PET) but mostly ends up on landfills or finds usage for environmentally unfriendly energetic applications.

6

Especially mixed plastic waste from households ends in incineration or landfills, both causing environmental harm.

7

TUBIS offers a solution that can lead to a full lifecycle of plastic material through chemical recycling for further usage as feedstock for the chemical industry.

What we do

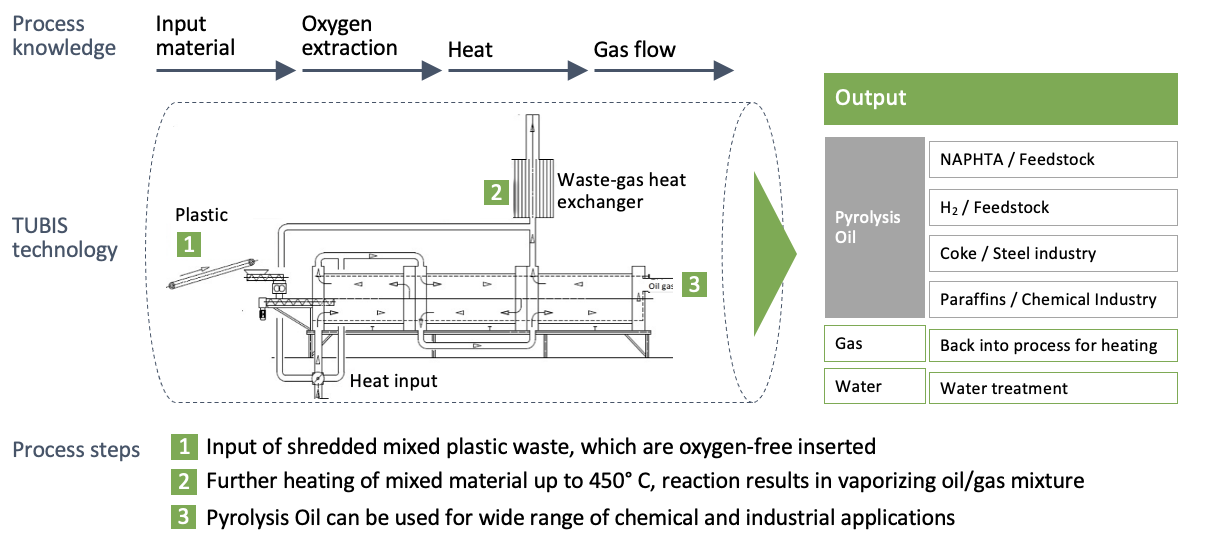

- TUBIS uses a pyrolysis process to convert previously unusable mixed plastic waste back into high quality petrochemical products.

- We offer a solution that can lead to a full lifecycle of plastic material and provide a true recycling process.

- TUBIS collects mixed plastic waste from classical recycling and waste management companies as well as industrial Clients under long-term supply contracts.

- The process can use any kind of mixed plastic waste that today would be incinerated in concrete plants or in waste incineration e.g. plastic bags and bottles, as well as potato chip bags or yogurt containers.

- In the pyrolysis process the mixed plastic waste (up to 24.000 tons per year and plant) is heated to the point where the hydrocarbons are cracked, so that shorter-chain hydrocarbons evaporate from the hot oil mixture. The end result of this process is an oil-gas-vapor mixture which is cooled and separated into low-sulphur oil and gas.

- While the produced gas is used to continuously heat the reactor into the production process, the oil can be employed for energetic purposes or as feedstock for industrial applications such as plastics, lubricants, rubber or fertilizer.

THE MISSION

We make this world a cleaner place by reducing plastic waste and reusing existing fossile fuels to create full circularity

OUR PROCESS

ADDING VALUE

The central element in environmental sustainability is to close the cycle of products. The aim is to conserve natural resources by lowering the quota of materials used and reducing the burden of disposal capacities. To this day, only roughly half of plastic waste in the EU is mechanically recycled whereas the rest is used as substitute fuel or even ends up on landfills.

TUBIS is a leading eco-pioneer and offers an integrated solution to fully meet the proposed targets of the European Green Deal by:

- Reinserting previously unused resources into the value chain

- Lowering CO2 production

- Creating a high value product from existing resources

The decentralized roll out of Tubis plants in Europe and beyond will strongly help to convert regional municipal and industrial mixed waste back into reusable products. With its first plant in Bulgaria, Tubis has proven its ability to run a constant pyrolysis process on industrial scale.